8

Better pork

August 2016

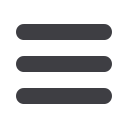

on slatted floors is organized more

generally into large open areas

subdivided by thigh-high, pre-cast

concrete panels that create pens for

static groups of 12 to 15 animals.

Competition for feed takes place

along the open troughs lining one

side of shared pen spaces of his barn.

In the open environment, unlike

stalls, docile animals can suffer.

Walkerton-based general contrac-

tor, John Ernewein Limited built

the structure. Countyline Equip-

ment Ltd. of Listowel installed an

Automated Production Systems

(AP) chain feeder system. Geene

calculates capital cost per sow space

at about $2,000. The system lacks

electronic sow feeders, but they’re

under consideration.

The promise of electronic sow feeders

Computer-controlled feeding and

recording systems for hog produc-

tion promise reduced social pressure

in group housing and possible new

efficiencies. The machines recognize

tagged individuals and distribute

feed accordingly.

They allow customized feeding

for individual needs and would ac-

commodate a move Geene is also

considering from relatively small,

“static” groups to larger “dynamic”

groups.

“Then it’s just one big party in

there,” he said, referring to the po-

tential for reduced social pressure in

larger groups. “Maybe it’s because

some of those docile sows could stick

together in a corner.”

Geene is also waiting on better

technical evidence about the location

of electronic feeders in large-group

floor plans. What’s attractive about

them is the potential to manage

individual rations “especially for gilts

or bigger sows,” he said.

Although he’s part of a genera-

tion of farmers familiar with digital

technology, Geene remains con-

cerned about technical complexity in

electronic feeders.

“I don’t want to be in the barn all

the time,” he said. “You’d still have

to train employees and I think that

would be an issue.”

“And then, Murphy’s Law, it

breaks on a Sunday or when you’re

out in the fields planting. My feed

system broke when I was planting

too, but it’s just a quick little fix.”

Challenges with changing social behaviour

Group management and changes

in social behaviour with an ageing

sow cohort are the largest challenges

Geene has faced. It’s part of the

reason he’s moving to larger batch

farrowing groups — to better match

sows for size and maturity.

“It’s not like stalls; you put ’em in

and walk away,” he said. “I can’t just

take one and say, ‘Oh, this one’s get-

ting a little skinny, I’ll put her in with

the skinny girls; you can’t do that.”

At startup with a group of

first-parity sows, the animals were

fairly uniform in size and age.

Since then, the introduction of new

animals and the retention of others

have created growing herd disparity

in size and ages.

“I find the older sows don’t put

up with as much; they’re a little

grumpier when somebody comes in

their little area and they know the

system. They know they’ve got to

eat ’cause that’s all we’re getting for

today, so I think they’re a little more

aggressive,” Geene said.

BP

Group management and changes in

social behaviour with an ageing sow

cohort are the largest challenges

Geene has faced.

MAIN

FEATURE