10

Better Pork

June 2016

COVER

STORY

1961, 1983, 2000 and 2003, he and son

Mitchell have introduced most of the

precautions mentioned in the ministry’s

fire guide. Lights in the newest barn are

sealed, as required by the provincial

electrical code. In rooms and hall-

ways, he uses outdoor receptacles with

waterproof seals to prevent wash water

from seeping in. Periodically, he clears

dust from fan heaters, ceilings and

other equipment that can’t be cleaned

with a pressure washer. A trusty leaf

blower eliminates debris in areas that

the air compressor hose can’t reach. The

blower “works really well for cobwebs

and stuff like that,” he says.

Precautions go beyond cleaning rou-

tines and special plugs. A heat exchang-

er system housed in a 40-foot room

adjacent to the newest barn not only

warms air but also prevents dangerous

gas buildup. The hot water boiler system

is less of a fire risk than other heating

types. In the attic are fire stops (barrier

walls). Fire extinguishers are handily

located throughout the main floor, as

are escape doors.

Van Engelen uses sprinklers in the

newer barns to soak rooms for pre-

washing and cooling the pigs and also

uses alarms for feed and hydro to gener-

ate alerts for power outages and equip-

ment malfunctions. The alarms connect

to his phone.

Linking a fire alarm to a sprin-

kler system, however, is expensive. A

sprinkler system alone can cost between

$100,000 and $150,000. Van Engelen

estimates that integrating an alarm sys-

tem with sprinkler activation would cost

thousands of dollars. “Maybe in the fu-

ture we might be able to use something

like that, when the technology makes it

simpler,” he says.

Farm builders’ concerns

Sprinklers pose other problems. Many

barns source water from wells and use

waterlines that don’t have the capacity

to provide the pressure such systems

need, says Steven Adema, an engineer

with Tacoma Engineers in Guelph.

Moreover, if a fire knocks out electri-

cal power, how are you going to pump

water to the barn?

Adema’s firm belongs to the Cana-

dian Farm Builders Association and,

during the association’s annual meeting

in January, attendees raised concerns

that public pressure will foist unrealistic

requirements on barn construction to

address fire safety.

Beneath that concern, says Will Ter-

on, Adema’s Tacoma colleague, lurks

the fear that the provincial government

will remove the National Farm Building

Code as the reference for barn construc-

tion in the provincial code. The national

code recognizes the unique aspects of

farm buildings, such as their low human

occupancy, remote locations and special

occupants. But its last update was in

1995 and buildings have become much

larger since then. What if the province

responds to public pressure by reclassi-

fying barns as industrial buildings?

Manitoba went that route in 2010

and, under its provincial building code,

barns of more than 600 square metres

are classified as either medium or light

industrial. The classifications contain

provisions for sprinkler systems and

firewalls. Facilities that have fewer than

75 employees do not need an alarm

system, but both classifications require

an emergency plan. A 2009 discussion

Ontario barn fires: what

the statistics show*

Number of fires

2013: 4

2014: 12

2015: 16

2016 (to the end of April): 14

Volume of dead stock

2012: 180 MT

2013: 155 MT

2014: 175 MT

2015: 225 MT

2016 (to the end of April): 306 MT

(70 per cent of the figure was from

one fire)

*These statistics reflect instances when the Ontario Min-

istry of Agriculture, Food and Rural Affairs had provided

the farmer with information on regulatory requirements to

responsibly manage dead stock. Source: OMAFRA

The main causes of

barn fires*

According to Ontario’s Office of the

Fire Marshal, insurance companies

and contractors, the primary sources

of ignition in barn fires fall within

the following categories:

• miscellaneous (chemical reac-

tions, such as combustion and

lightning)

• electrical distribution equip-

ment (circuit wiring, distribution

equipment, extension cords,

etc.)

• heating equipment (central

heating, flue pipe, space heat-

ers, etc.)

• open flame (cutting/welding,

blowtorch, smoking, etc.)

*Contributed by the Ontario Ministry of Agriculture, Food

and Rural Affairs

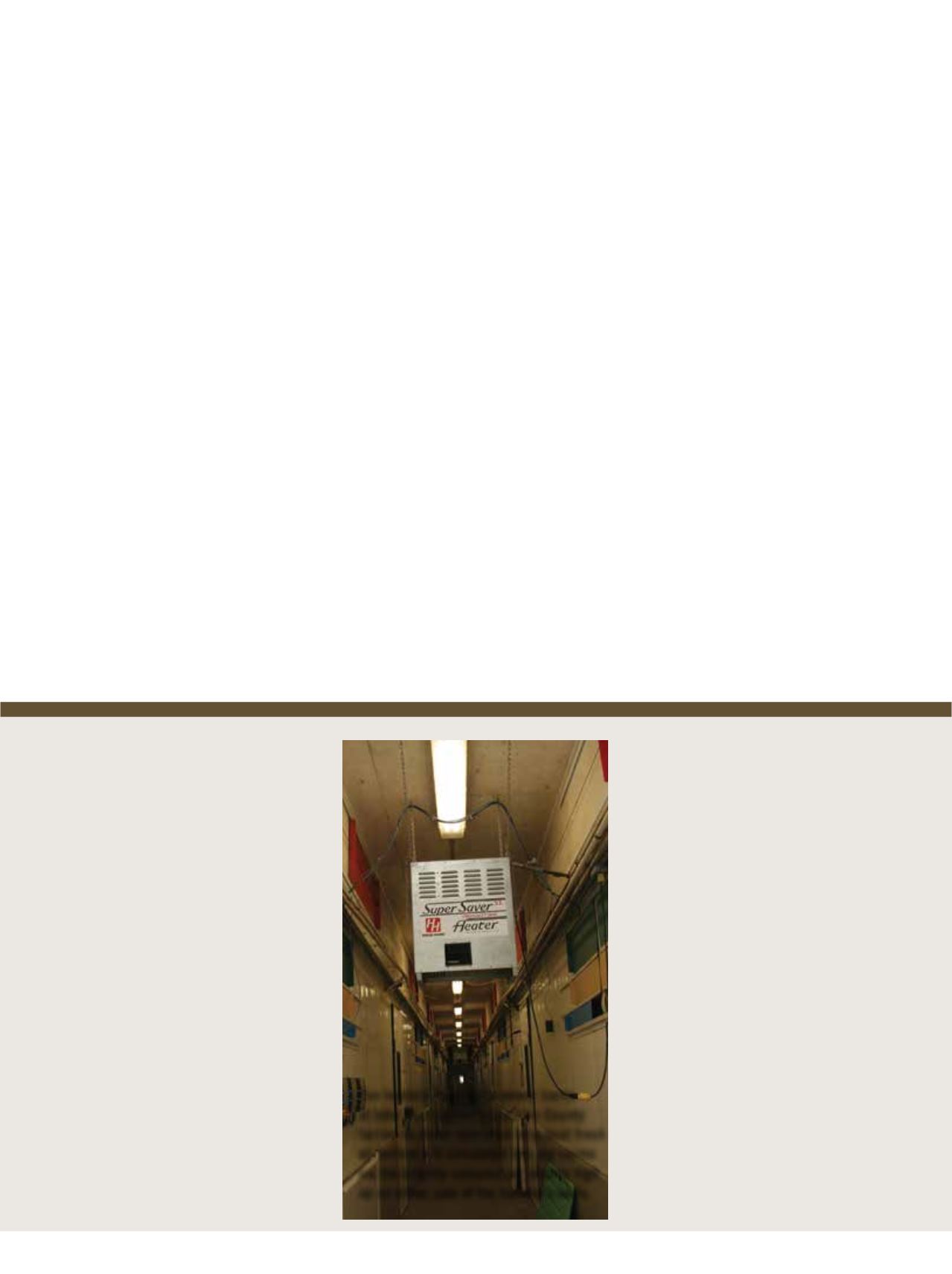

Fan heaters used in the newer barns

at John Van Engelen’s Lambton County

farrow-to-finish operation help heat fresh

air before it is circulated into pig rooms

via the brightly coloured air returns high

up on either side of the hallway’s walls.