Better Pork

December 2016

7

COMPUTERIZED

HOG

BARN

HOGBARN

that his operation gained from new

technology employed by his genet-

ics and feed suppliers. Regarding

the use of technology on the farm,

Adam noted a clear generational

difference between himself and his

parents. But he also described Clare

– a high-profile former Ontario

Pork chair and former Canadian

Pork Council president – as an early

adopter of computer technology.

The increasing availability of

computer technology for livestock

management and recent changes to

Canada’s Code of Practice for the

Care and Handling of Pigs mandat-

ing greater movement for gestating

sows in pens appear to have prompt-

ed a round of new investment in

buildings and renovations. Numbers

and costs are hard to come by, and

the size of such investments varies

widely.

In the emerging age of robotic

tractors and global positioning

systems (GPS) to guide precision

field work, smart barns seem almost

inevitable. Robots are already in

use in dairy barns to milk cows and

sweep floors.

In a smart hog barn, robots can

powerwash stalls and lead can-

tankerous boars. There are digital

machines to detect the heats of sows

and to feed, water and weigh pigs.

Other machines manage feed inven-

tory, ventilation and manure stor-

age; still other machines assess the

health status of and financial returns

on a batch of pigs.

University of Saskatchewan

ethologist Jennifer Brown, who

heads Canada’s National Sow Hous-

ing Conversion Project (NSHCP)

to educate producers about group-

housing techniques, described a

Spanish feeding system that in-

corporates weigh scales capable of

matching feed records with the body

weight of individual animals. New

data is one side-effect of the current

shift to group housing for sows and

the adoption of ESF technology.

“We do expect to see more regu-

lar monitoring and individual moni-

toring that allows you to manage

individual pig data,” Brown said in

an interview from her Prairie Swine

Centre office in Saskatoon. She cited

recent research at both the Univer-

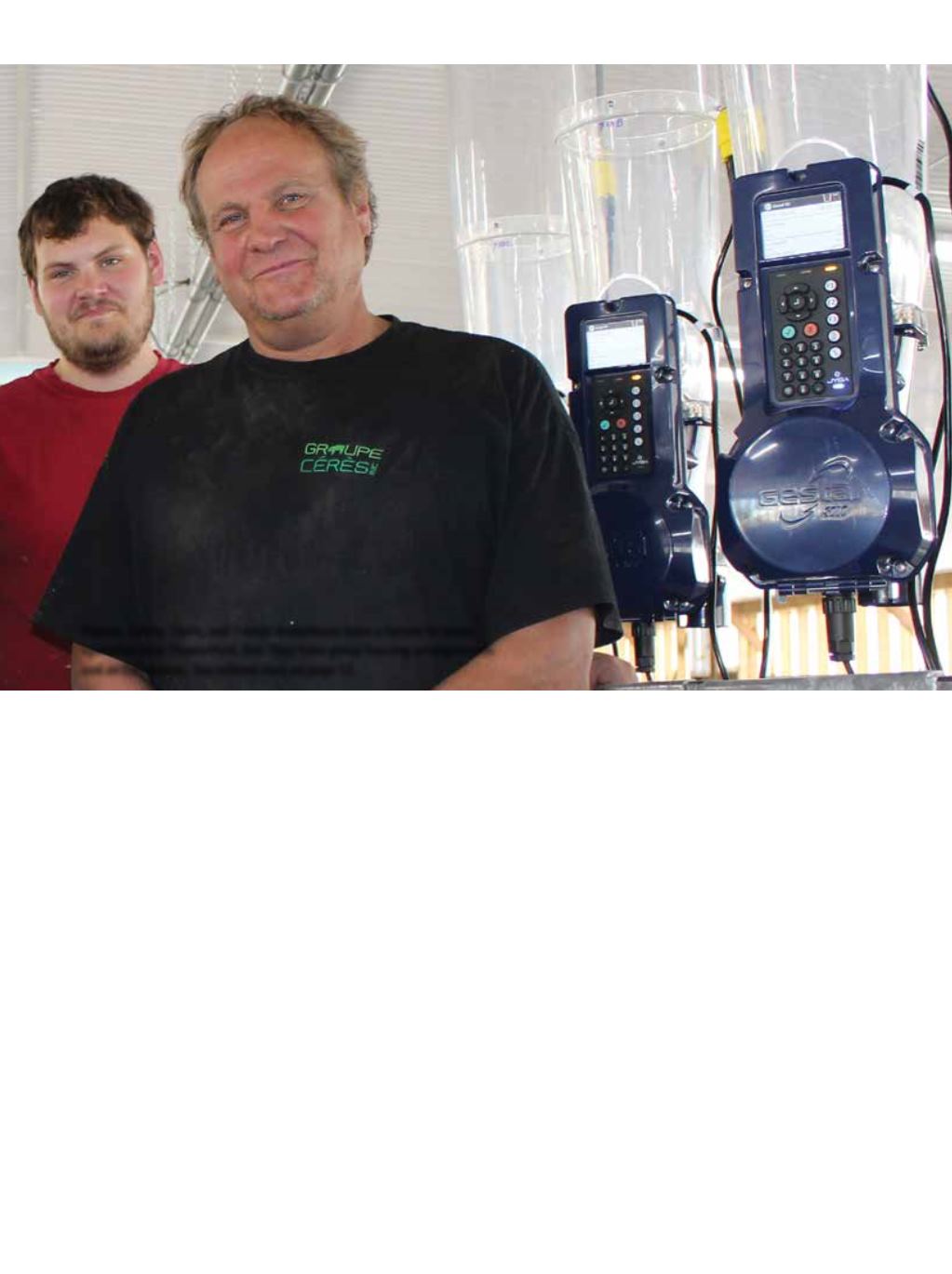

Dianne, Calvin, Travis, and Francis Brekelmans have a farrow-to-wean

operation near Thamesford, Ont. They have group housing arrangements

and an ESF system. See related story on page 12.