‘It can be introduced at any point in time in an operation & has benefits.’

By Emily Croft

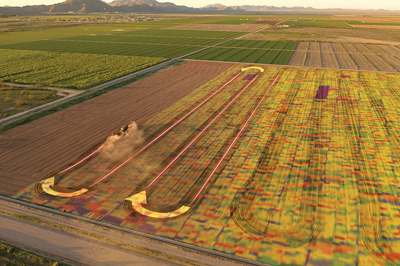

Guidance systems have become commonplace on Ontario farms as precision agriculture technologies grow in popularity. Various available features and accuracy levels mean farmers can choose a guidance system that best suits their operation’s needs.

“Guidance systems can be useful for everything from fertilizer application straight through to planting, tillage, and hay,” says Jordan Wallace, sales and advanced solutions technician at GPS Ontario.

“A guidance system is meant to make it easier to farm, not make it harder to farm. Every farm will benefit from a guidance system regardless of how large or small. There are many different levels of guidance systems.”

Kendal Quandahl, manager of the Case IH Precision Field Team, says that there are a few ways these systems help producers.

“Guidance is something that can be introduced at any point in time in an operation and has benefits,” says Quandahl.

“It can reduce inputs by avoiding overlaps and helps producers make better use of land. It also helps minimize operator stress and fatigue. If you are steering the tractor, controlling the implement all day long – 12, 14, maybe 16 hours a day – you get tired. And when you get tired, we all get a little less efficient.”

For producers looking to take advantage of these benefits, there are a lot of choices to be made in selecting the right system for an operation.

What’s available?

Rapidly changing technology and an abundance of options can complicate the search for a new guidance system.

Wallace explains that guidance systems can range from basic monitors to full steering systems.

“At your basic entry level, you’re going to have your light bar and mapping systems where the operator is given a coloured map or set of lights to follow that guides them for manual steering,” says Wallace.

“The next step up is an electric motor added to the side of the steering wheel or a replacement steering wheel, and it physically turns the steering wheel for the operator. The next level is automated steering systems, which are hydraulically plumbed into most newer tractors. This is faster responding and has smoother steering.”

Case IH offers two categories of guidance systems.

“The first guidance system type we offer are hydraulic guidance systems. These come with all the equipment to steer the tractor built into equipment. In many cases, it is standard equipment from the factory now,” says Quandahl.

“We also have options through our CNH Industrial parts that would allow a customer to upgrade older equipment or equipment that didn’t come with it from the factory. It gives producers the option to add a display and motor to the steering wheel in the cab or add upgraded equipment at a lower price point.”

Ag Leader also offers two levels of systems, says Ben Vaarkamp, GPS specialist at O’Neil’s Farm Equipment in Binbrook.

“SteadySteer is a motor drive system that is mounted on the steering wheel. It physically turns the steering wheel,” says Vaarkamp.

“The motor is quickly removable when producers don’t need guidance, like if they are pulling wagons and they don’t want to wear out the motor. That’s the entry level for steering and it has a very good success rate. I have lots of guys running them.

“Next step is full hydraulic. With that, you have vehicles that are guidance ready, and that is mostly plug and play, but older tractors might need more components to make it steer hydraulically.”

After looking at system type, producers should evaluate what accuracy they need for their management practices.

Accuracy

When determining the accuracy needs of their farm, producers should consider which management practices they would like to implement and if they will need the system to be accurate year-over-year.

“Either hydraulic or electric systems can be calibrated or tuned to be accurate from an operation standpoint,” says Quandahl.

“A lot of people are looking to increase accuracy to make better use of ground and make sure they know exactly where they are.”

Many upgrades to GPS accuracy are based on subscription systems and will come at an extra cost.

“On the Trimble side, there’s RangePoint RTX, which has six-inch pass-to-pass accuracy and 15-inch year-to-year accuracy, and that runs around $630 a year,” says Wallace.

“CenterPoint RTX is the next step up, with one-inch pass-to-pass accuracy and one-inch year-to-year accuracy, and that subscription is $1,300 a year.”

Wallace says that improved year-to-year accuracy is key for some tasks that require precision.

“Pass-to-pass accuracy would be the accuracy within 15 minutes, but the guidance world really opens up in year-to-year functionality,” explains Wallace.

“A small beef farmer who is just spreading fertilizer and harvesting hay probably won’t want to pay for signal, but a strip-till guy probably wants the year-to-year accuracy because you want that fertilizer to come in where you’re banding. If you’re off fertilizer by three inches you will lose 15 to 18 per cent of yield potentially. If you’re a foot off-line you can lose 70 per cent of yield.”

Vaarkamp says that another way of looking at accuracy, specifically for those with fruit and vegetable crops, is at how slow of a speed the system will remain accurate.

“With SteadySteer, you can go as slow as a mile per hour. You can go from basic accuracy, all the way to RTK sub-inch accuracy at that speed,” explains Vaarkamp.

“With a hydraulic system, you can go as low as a half-mile an hour and go up from there. One product we offer is DualTrac, which is a double antenna for ultra-slow operations. It goes as slow as 80 meters an hour, and that can hold sub-inch accuracy. It’s great for guys doing transplanting, because they are going so slow and want to keep that straight line.”

As technology evolves, many dealerships offer guidance systems that come with additional features.

Additional features

One common additional feature offered with some guidance systems is end-of-row turning assistance.

Ag Leader has offered this feature with both their SteadySteer and hydraulic systems since November 2023.

“TurnPath looks to be a very promising feature for steering assistance,” says Vaarkamp, noting that compatibility with an electric motor turning system is unique to Ag Leader.

CaseIH offers a similar feature for their hydraulic systems, and Quandahl explains the benefits.

“AccuTurn is an automated end-of-row turning option,” says Quandahl.

“We can command the tractor to turn around on its own at the end of the row, so you hit the next guidance line with more accuracy. You typically have to raise the implement, turn around, and sometimes have to square up. With AccuTurn you can hit that exactly square.”

Another feature that may be of interest is a system’s ability to collect and integrate data. This can be valuable for assessing the cost of production, as well as improving precision in the fields.

“Is managing your farm data important? Then you want something that stores and collects data for you, and allows you to integrate that,” says Wallace.

“On my operation, when I input the data into software, I can associate a dollar value into the task. It can calculate custom work rates on the implement itself and I can also put an hourly rate to the operator by selecting who’s on the seat.”

The extra features available with guidance systems can help producers improve efficiency and management in their fields.

OEM versus aftermarket

Guidance systems are available from many original equipment manufacturers (OEM) or available as aftermarket upgrades. There are some benefits to both sources.

“Using an OEM system makes it a little bit easier for customers as they move between different machines,” says Quandahl, noting the consistent experience that OEM systems provide.

“I don’t have to try to think about which function I’m using. It’s a very cohesive experience and it makes it a lot easier for producers as they move between different options.”

Wallace notes that OEM systems work well for producers who have a consistent fleet of tractors, and frequently move between equipment of the same brand. It might also make for a lower cost of entry.

“But that doesn’t mean that’s where you have to stop.”

OEM brands of guidance systems typically work best on equipment of the same brand. When seeking out a new system, sometimes aftermarket systems can integrate more easily.

“That also comes down to your three-to-five-year goal,” says Wallace.

“Do you want to integrate into other tools you have on your farm and capture that data while limiting displays in the cab? If that’s the case, then you probably want to stick with Trimble or Ag Leader at that point.”

How to choose

How does a producer assess all these factors to choose the right guidance system for their farm?

“It’s going to come down to the goals of their operation,” says Quandahl.

“One of the easiest ways to start is looking at what equipment they have today. Are they in a smaller utility tractor where we could easily add an electric system to their machine? Or if it’s a bigger Case IH Magnum or Steiger, that equipment may already have some parts for guidance in the machine.”

Wallace says that part of determining the goals of the farm is also reviewing their immediate need and pay point.

“Is it ‘I just want autosteer to be more efficient,’ or is their immediate goal to be more accurate pass-to-pass, or is it to create a data set? If the immediate need is for accuracy, find a display with good service and support to get started.

“But before anything is purchased, the farmer needs to look at where they want to be in three to five years on the farm.”

Wallace points out that considerations such as eyesight and ease of use can be important.

“Is the producer’s eyesight going to get worse in the next three to five years?

“The farming population is getting older, so a smaller monitor might not be the smarter move. The extra $800 up-front may let you operate easier and more consistently up the road,” explains Wallace.

Price point is another deciding factor for producers.

“Most systems are in the same relative value. Basic guidance systems with manual steering will be in the $2,500 to $5,000 range. Implementing assisted steering will be around $7,500 to $20,000, and fully integrated systems will be around $15,000 to $30,000,” says Wallace.

The final factor that should play into a decision is the available support from dealers.

“If you can’t get support for your system, it’s not even worth looking down that road,” says Vaarkamp.

“This is where Ag Leader shines. As a producer, when you buy an Ag Leader system, you can call their tech support, so you don’t actually have to go through the dealer if you can’t get hold of them.”

He also explains that talking to a dealer is a good way to make sure you get the best system for your equipment and goals.

“If it’s a techy producer, they can do a lot of the research themselves, but usually it comes down to the dealer and what the producer wants to do,” says Vaarkamp.

“That’s usually where the dealer will figure it out. They will do the research for the producer, visit the farm, see the operation and what they are trying to achieve. And they know the product inside and out.”

No matter which system producers choose, Quandahl says that a good guidance system “will help a producer be more consistent and effective for their entire day.” BF

Post new comment